Services

Ultrasonic Anilox Cleaning Machines

Specialized cleaning equipment ensuring optimal performance of your anilox rolls.

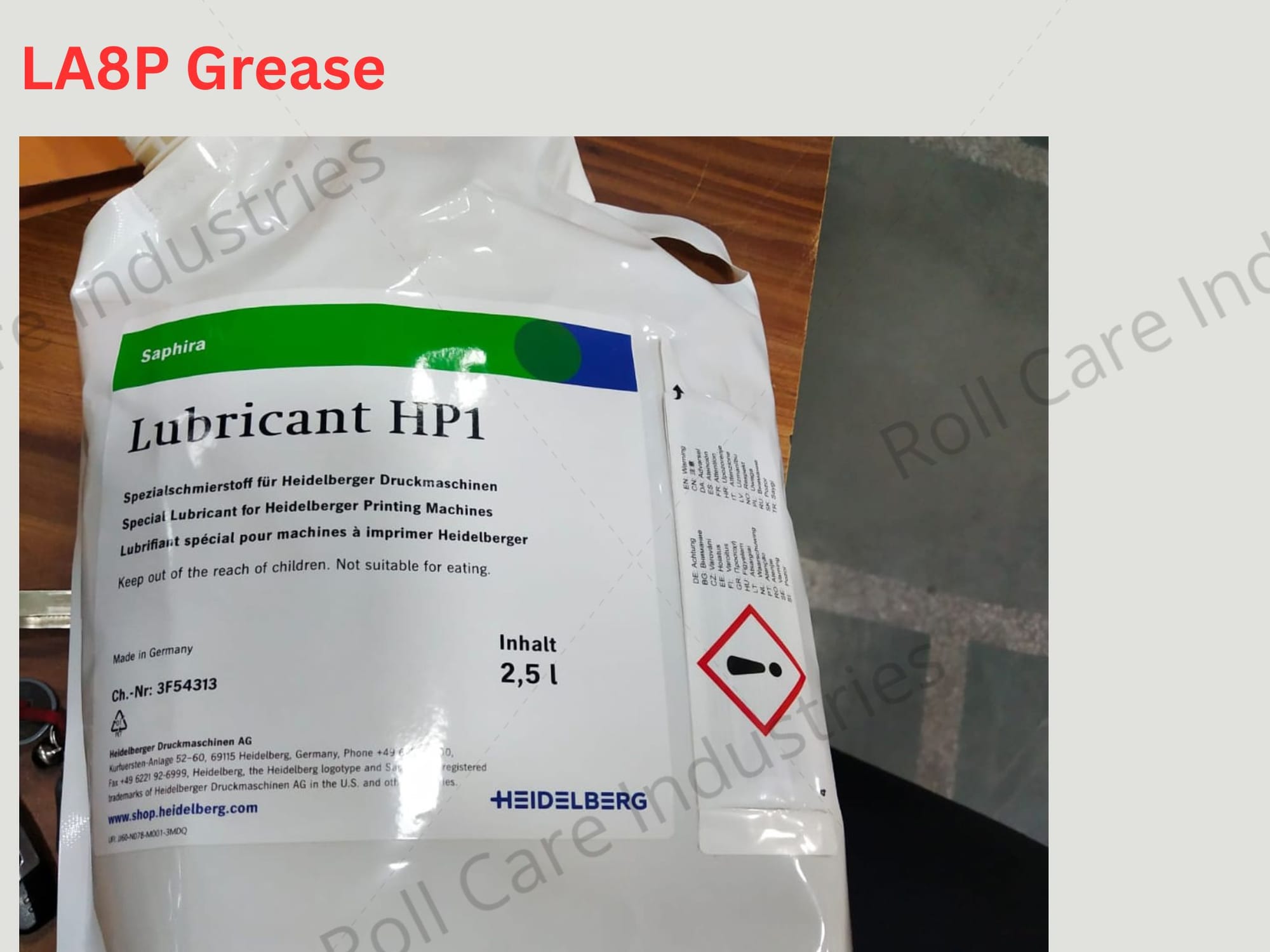

High-Performance Cleaning Chemicals

Eco-friendly and effective solutions for maintaining equipment cleanliness.

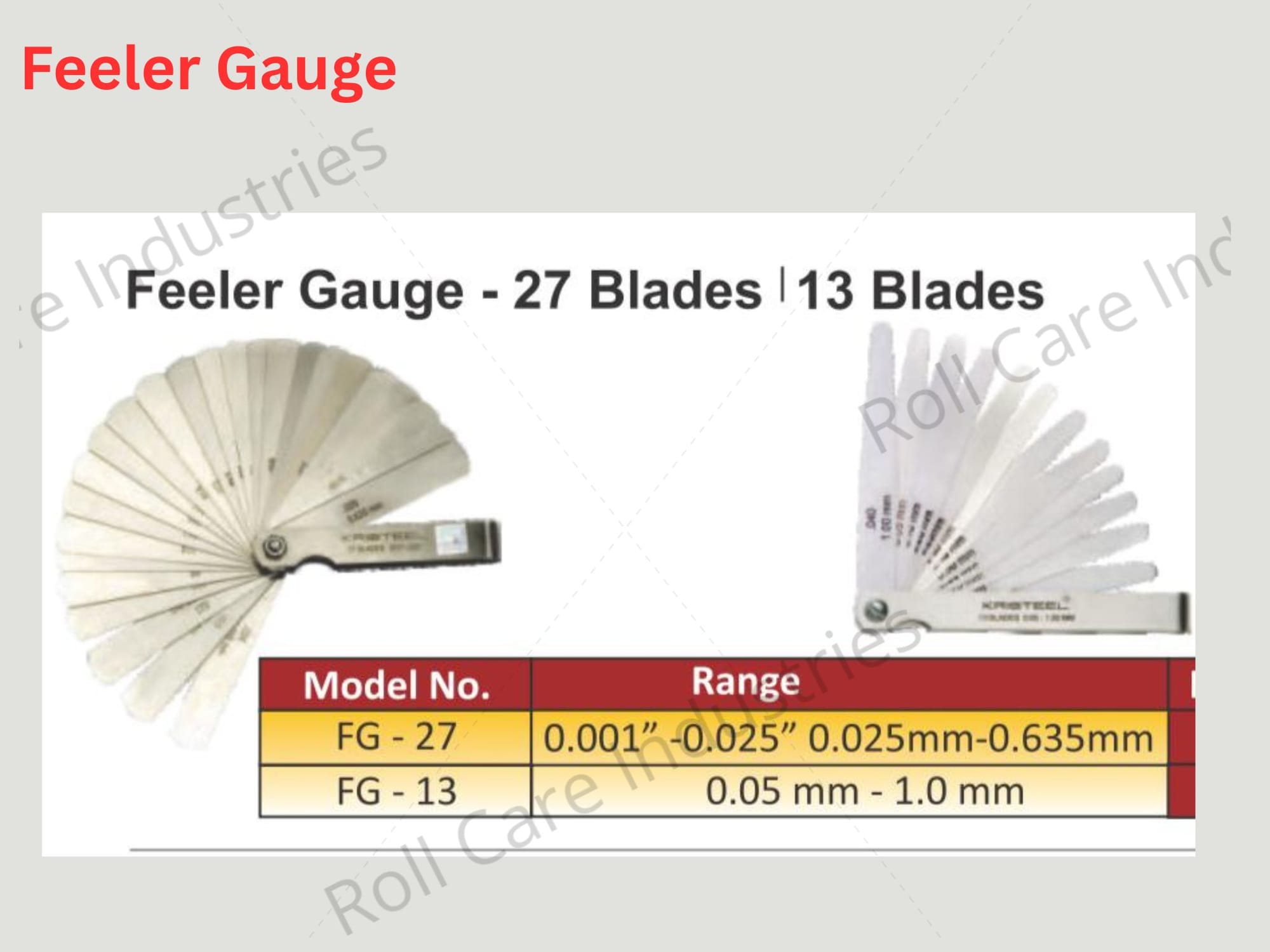

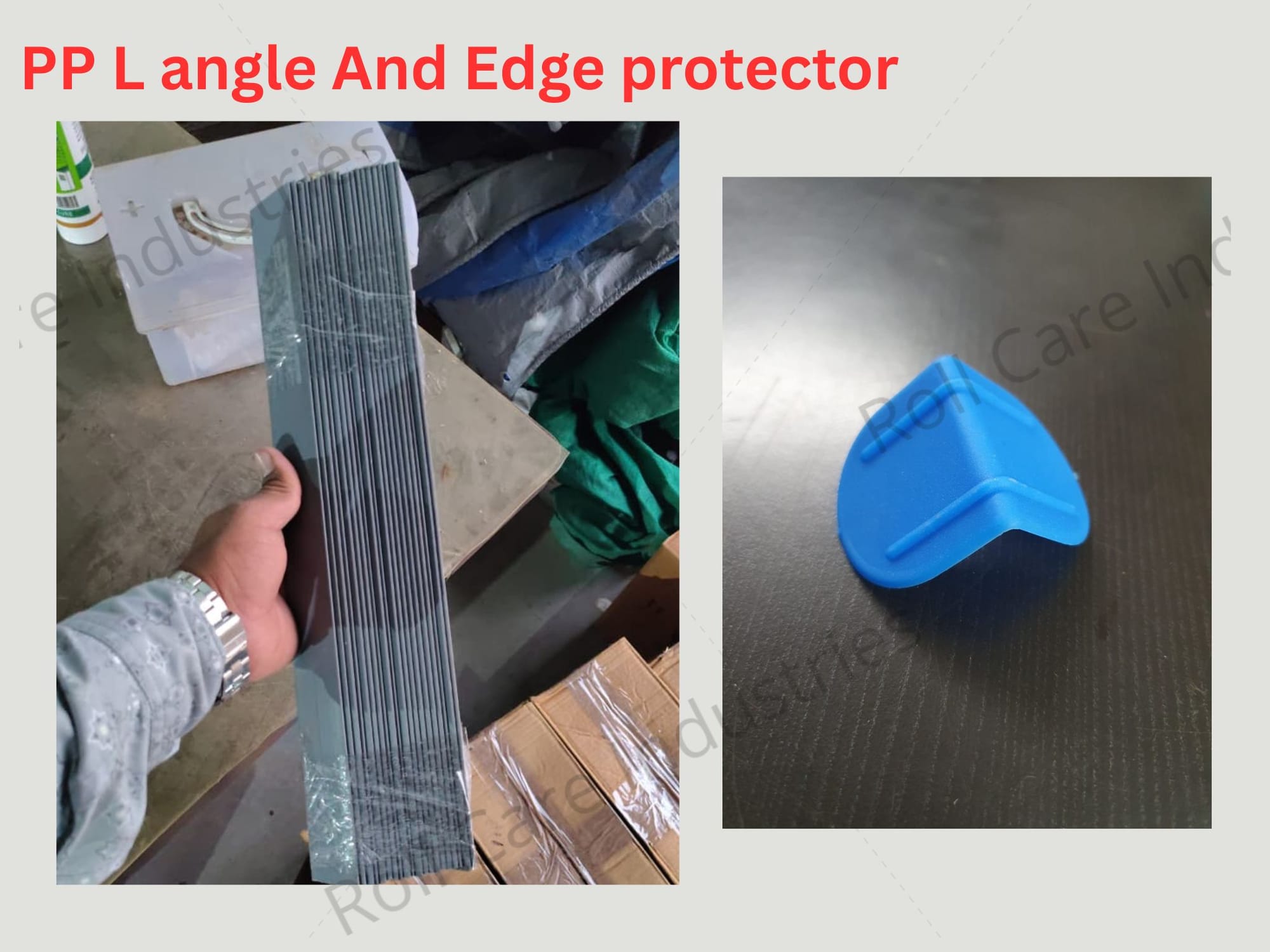

Customized Maintenance Tools

Tailored tools designed for seamless flexographic printing upkeep.

Ship your rolls to us

anilox roll cleaning service

Clean Your Anilox Rolls with Roll Care Industries Ensure optimal print quality and extended roller life with our advanced ultrasonic cleaning solutions. We efficiently remove: Ink, coating, varnish, and adhesive residues From ceramic anilox rolls and sleeves Offset coating rollers Gravure cylinders Our controlled ultrasonic process restores cell volume without damaging ceramic surfaces, making it safe for both coarse and fine screen anilox. 📦 Need guidance on safe packing and shipping of your rolls? Our technical team is happy to share proven best practices to avoid transit damage. Roll Care Industries Anilox Care | Cleaning | Maintenance | Expertise 📞 Contact: 90231 55302

Anilox Products

Anilox Base roll SS, MS and Aluminum

"The "Anilox Base Roll SS, MS, and Aluminum" service provides custom manufacturing and maintenance of stainless steel (SS), mild steel (MS), and aluminum Anilox base rolls used in printing applications. These rolls are crafted to high precision standards to ensure optimal performance and longevity, catering to various industry specifications."

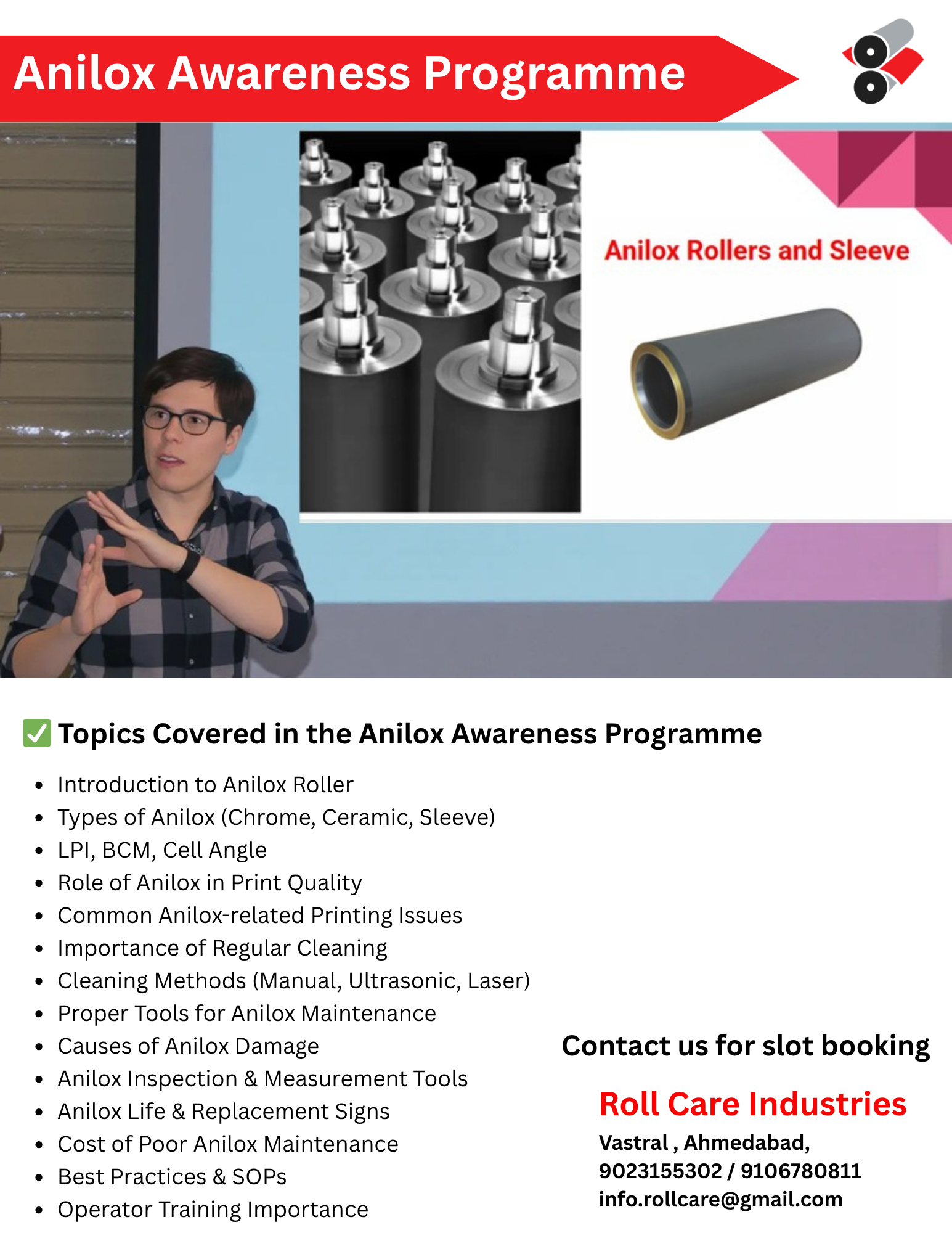

Anilox Roller

Anilox rollers are integral components in the flexographic printing industry. They are designed to transfer ink onto printing plates with precision, ensuring uniform and accurate printing results. Constructed from high-quality materials, these rollers are engraved with fine cells that meticulously control ink distribution. Industries utilizing flexographic printing rely on the quality of anilox rollers to achieve superior production standards, catering to a wide range of packaging and labeling needs.

Anilox Sleeve

The Anilox Sleeve is a specialized tool used in the printing industry, designed to transfer a precise volume of ink or coating onto the substrate surface. Its high-quality material and precise engraving ensure uniform ink distribution for consistent print quality. Our Anilox Sleeves are available in various configurations to meet the specific needs of your printing processes.

Rubber Roller Flexo Industries

Rubber Roller Flexo Industries

Roll Care Industries manufactures high-quality Rubber Rollers for flexographic printing machines, designed to ensure smooth ink transfer from the chamber to the anilox roller. Built with precision and durable rubber compounds, our rollers provide excellent chemical resistance, consistent performance, and long service life. A reliable solution for the flexo industry, our rubber rollers help achieve accurate printing and reduced downtime."

Anilox Cleaning Ultrasonic Machine Manufacturer

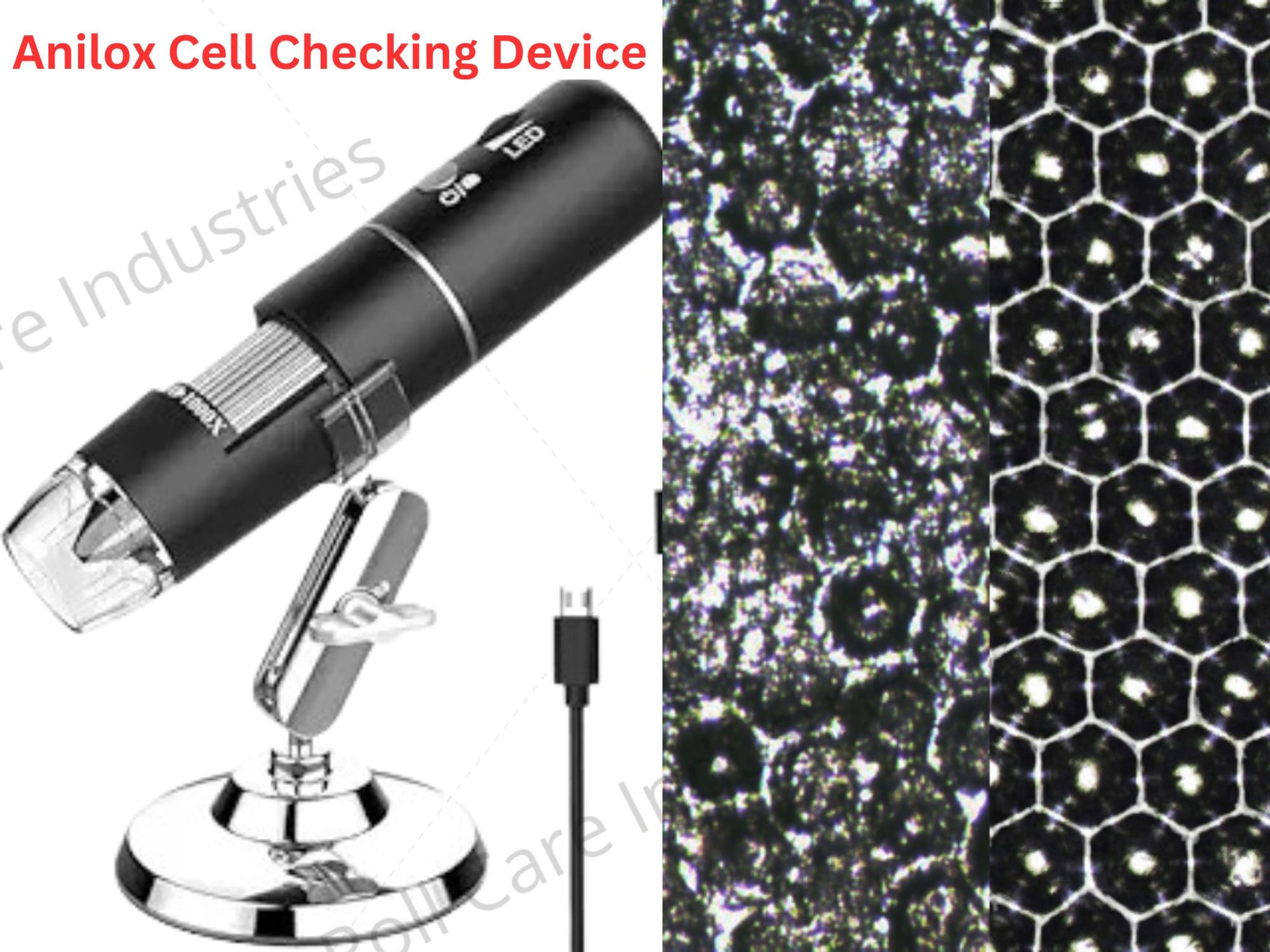

The Roll Care Industries Ultrasonic Anilox Roller Cleaning Machine is engineered for precision, safety, and superior cleaning performance of ceramic and chrome anilox rollers used in flexographic, gravure, and label printing industries. Designed with advanced ultrasonic technology, it restores the original cell volume of the roller without causing any damage—ensuring consistent ink transfer and high-quality printing results.

Unlike traditional manual or chemical cleaning methods that often leave ink residues, the Roll Care Industries Ultrasonic Cleaning Machine uses high-frequency ultrasonic cavitation to effectively dislodge dried inks, coatings, and adhesives from even the tiniest anilox cells. This deep and uniform cleaning process enhances roller life, reduces maintenance effort, and maintains stable print performance.

Crafted from premium-grade stainless steel (SS304/SS316), the unit ensures outstanding durability, corrosion resistance, and long service life. Equipped with a digital temperature and timer control system, it enables precise and repeatable cleaning cycles every time. The non-contact cleaning process eliminates the need for manual scrubbing, reducing operator fatigue and ensuring a safer, eco-friendly working environment.

With low chemical usage, reduced downtime, and environment-friendly operation, this machine is the ideal choice for modern, sustainability-focused printing facilities. Roll Care Industries also offers custom-built systems suitable for single or multiple rollers, varying roller lengths, and different ink systems. Safety features such as overheat protection and emergency shutoff make operation completely reliable.

Key Benefits of Roll Care Industries Ultrasonic Anilox Roller Cleaning Machine

- Deep removal of inks, coatings, and contaminants from microscopic anilox cells

- Gentle, non-contact cleaning—no mechanical wear or damage

- Improved ink transfer and sharper print quality

- Reduced cleaning time, labor effort, and downtime

- Eco-friendly operation with minimal chemical use

- Compatible with water-based and solvent-based inks

- Stainless steel body for durability and long service life

- Optional customization for roller size, type, and application

Backed by years of research and innovation, the Roll Care Industries Ultrasonic Anilox Roller Cleaning Machine delivers unmatched reliability, performance, and quality assurance.

For superior cleaning efficiency, longer roller life, and maximum productivity, trust Roll Care Industries—your complete partner in professional anilox roller care and maintenance.

Anilox Roll Cleaning ultrasonic Machine

Anilox Roller Cleaning Ultrasonic Machine

"Roll Care Industries offers advanced Anilox Roller Cleaning Ultrasonic Machines, specially designed for deep and precise cleaning of ceramic anilox rollers. Using ultrasonic technology, these machines generate microscopic bubbles that safely penetrate anilox cells, removing dried inks, coatings, and contaminants without damaging the ceramic surface. Easy to operate and highly efficient, our ultrasonic machines restore original cell volume, improve ink transfer, and extend roller life—ensuring consistent, high-quality printing."

End Seal Products

Foam Type End Seal

"Roll Care Industries manufactures high-quality Foam Type End Seals for flexographic printing machines, designed to provide excellent chamber sealing and prevent ink leakage. Made from premium foam materials with chemical resistance and durability, these end seals ensure proper doctor blade function, reduced ink wastage, and longer press life. Cost-effective and easy to install, our foam end seals are ideal for smooth and efficient press operations."

Felt Pad type End Seal

"Roll Care Industries is a leading manufacturer of Felt Pad Type End Seals for flexographic printing machines. Crafted from high-quality felt materials, these end seals provide excellent chamber sealing, prevent ink leakage, and ensure smooth doctor blade operation. Durable, chemical-resistant, and easy to install, our felt pad end seals help maintain consistent print quality, reduce downtime, and extend press life."

With Anilox Roll

& Doctor Blade

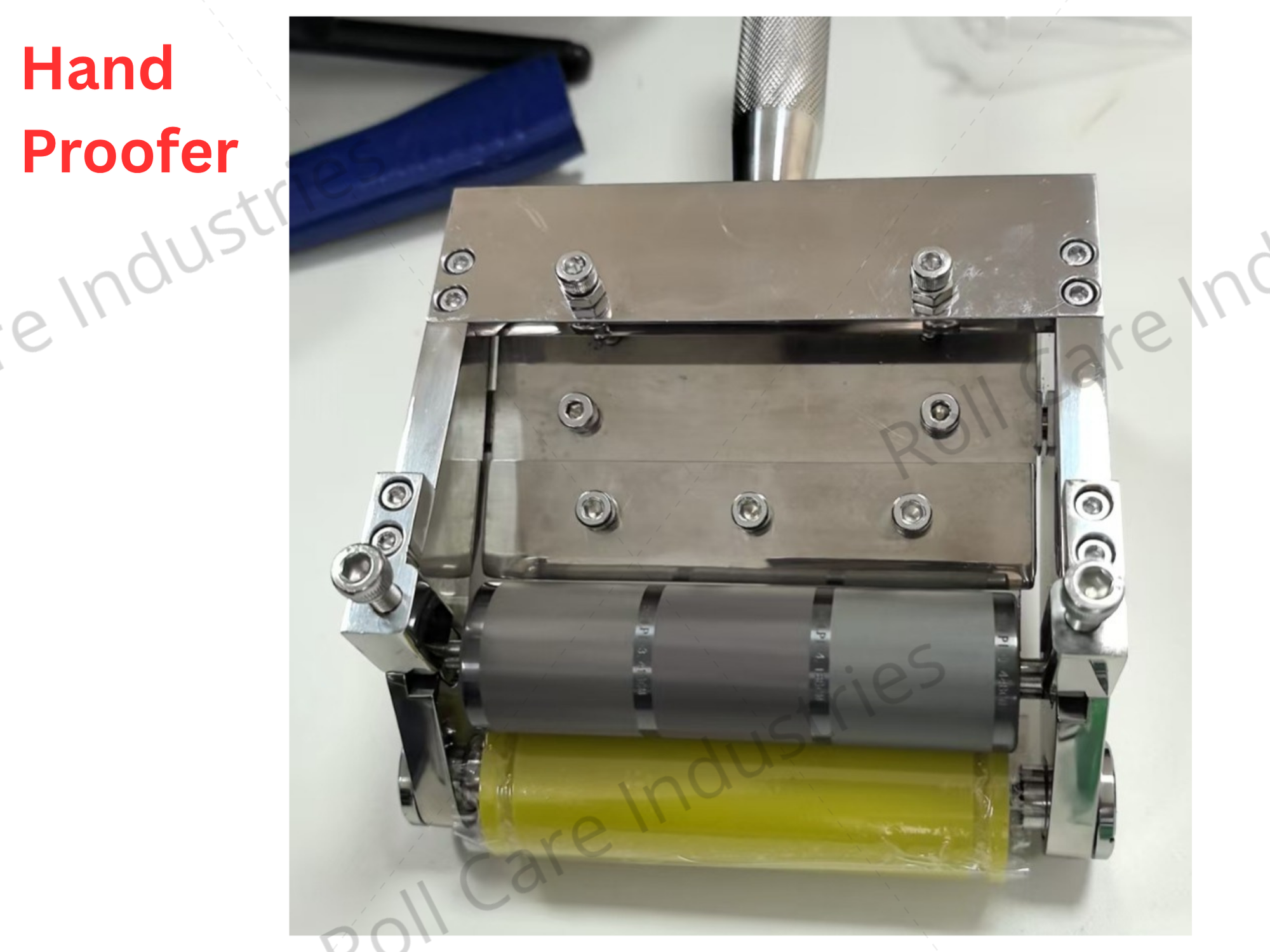

Hand Proofer for Ink color match

Hand Proofer for Ink color match

"Roll Care Industries offers precision Hand Proofers designed for accurate ink color matching in flexographic and gravure printing. These hand proofers allow printers and ink manufacturers to quickly test ink on substrates, evaluate color strength, coverage, and consistency before full-scale production. Durable, easy to use, and highly reliable, they are an essential tool for ensuring color accuracy and maintaining high print quality."

Hand Proofer Chrome Anilox Roll

The Hand Proofer with a Chrome Anilox Roll is designed for precise and consistent flexographic ink proofing. Its high-quality chrome-plated anilox roll ensures smooth ink transfer, accurate color density, and repeatable results, making it an essential tool for ink manufacturers, printers, and QC laboratories. Ideal for shade matching, ink formulation, and print testing, this hand proofer offers durability, stability, and reliable performance in every use.

Anilox Protection Cover

Special Designed Roll Care Round Brush

Digital Colorimeter

LS170 45°/0° Pocket Colorimeter

Roll Care Industries Supply LS170 portable and smart colorimeter is designed to provide users color measurement and color comparison of materials, because color control is important. It provides Bluetooth transmission and can be used with a powerful app designed by Linshang. After connecting to the app via Bluetooth, the colorimeter can quickly measure the color and make color comparisons on mobile interface. Besides, it has some electronic color charts in it and can quickly match the color code. You can share the color value to your friends.

LS171 D/8° Pocket Colorimeter

Roll Care Industries Supply LS171 is a smart colorimeter which can provide color scan and color comparison for materials. The colorimeter complies with relevant international CIE standards. It adopts D/8 illumination geometry and is equipped with a high-precision sensor that meets CIE. The colorimeter has good consistency and repeatability and need to be used with mobile app for accurate color measurement and quality control. Using this affordable colorimeter will boost your color quality when color requirements are too stringent to depend on visual evaluation alone. It is more accurate and reliable than other basic colorimeters.

Digital Colorimeter

LS173 D/8° Handheld Colorimeter

Roll Care Industries Supply LS173 is a portable multifunctional colorimeter with D/8° (SCI) optical geometry design. The color analyzer is equipped with a 3.5-inch IPS color capacitive touch screen, providing an excellent operating experience. The colorimeter integrates multiple natural color charts, and can quickly match the measured color to the closest color codes. The color difference meter also has a color difference comparison function, supports a variety of standard color addition methods, the color difference threshold can be set. The color difference formula can be flexibly selected, which can realize rapid QC testing.

LS175 Colorimeter with a Large Measuring Aperture

Roll Care Industries Supply LS175 is a handheld 45/0 illumination geometry colorimeter with a large 20mm measuring aperture, a 3.5-inch IPS color capacity touch screen, and can connect with mobile phone or PC. This device can work independently without connecting APP on mobile phone or PC software. Several color charts helps matching the closest color number of scanned color in short time. The device also has color comparison function, supporting multiple methods of adding standard. Availability of setting threshold of color difference ensures QC quick inspection. The device can connect APP and PC software, expanding its functions such as color sharing and printing reports.

Digital Colorimeter

LS176 Portable Spectrophotometer

Roll Care Industries Supply LS176 is a handheld multifunctional colorimeter with a 3.5 inch IPS color capacitive touch screen for an excellent experience. The instrument integrates many color cards, which can be matched to the nearest color card number for the sample color. It also has a color comparison function, a variety of color difference formulas to choose from, allowing for quick QC testing. The instrument meets the requirements about Grade 1 colorimeter in the Chinese JJG 595-2002 "Verification Regulation of Colorimeters and Color Difference Meters" in all directions.

LS177 Large Aperture Spectrocolorimeter

Roll Care Industries Supply LS177 large aperture spectrocolorimeter adopts D/8 illumination geometry, with 50mm large test aperture, specialized in color measurement and color comparison of non-transparent materials such as powder, masterbatches and so on. The spectrocolorimeter not only has various color spaces and color difference formulas, but also can display spectral reflectance curves, which is widely used in color management and quality control in the fields of paint, plastic, food, medicine and so on. The colorimeter also provides professional mobile APP and PC software to support data export and report printing.

F.A.Q

Blog

India’s No.1 Anilox Cleaning Brush Supplier – Roll Care Industries

Read MoreAn anilox roller is a precision component that directly influences ink transfer, print density, and overall print quality. Damage or mismatch during transportation or supply can lead to serious printing issues, machine downtime, and financial loss. Therefore, a structured receiving inspection is critical before installing an anilox roller on the press.This article outlines the essential checkpoints that must be verified immediately upon receipt of an anilox roller.

Read MoreWhite Ink - A Growing Challenge for Print Operators.

Read MoreTestimonials

Contact

- 143, Shree Hari Darshan Industrial Park, Phase IV, Vatva GIDC, Ahmedabad, Gujarat, India

- +91-9023155302 - 9106780811

- info.rollcare@gmail.com

- Mon-Sat - 08:00-19:00